Review – absoluteBLACK GRAPHENlube Bicycle Chain Lube

Can a bottle of chain lube ever be worth a 100 GBP expenditure? The new absoluteBLACK GRAPHENlube claims that yes, it can. The most scientifically advanced bicycle chain lube on sale today, this new graphene based dry lubricant can offer serious friction reduction, efficiency gains, and reduced component wear rates.

Wax-based lubricants show far greater tolerance to water and dirt contamination—successfully separating moving chain parts from abrasion and filling in all the imperfections on friction surfaces (see appendix).

Graphene—the wonder material (incredibly high cost) is a great chain lubricant additive for several reasons: it has an extremely low friction coefficient in all environments; it is far stronger than any other known material; it clings to metal surfaces such as chain parts; and it also repels water and is not permeable to air—reducing oxidative stress on metal surfaces. A single atom layer is enough to reduce friction.

It took absoluteBLACK two years to find the right ratio of crumpled to non-crumpled graphene; the correct size of graphene platelets; the dispersion rate of agglomerates; the best concentration; and to find a low-friction hydrocarbon emulsion base that would stay on the chain for a very long time and not chip away like paraffin wax. The result, is a new category of performance chain lubricant.

Graph 1 – Power Loss vs Distance

This test reveals how lubricant and friction changes over distance ridden. The higher the number, the more watts lost. With wet lubes, friction first decreases because the chain gets drier and therefore 'stiction' decreases; when it reaches a dry state, the friction then increases due to a starvation of lubricant and abrasion. For dry lubes, 'stiction' is minimal at the start—so friction simply increases due to the coating wearing out.

Why is this test important? When you pedal the force/torque is transferred through the chain to the rear hub. However, power generated at the crank does not equal power at the hub—due to frictional power losses.

How can we minimise this loss and keep it low for a long time? The answer, is through best possible lubrication. Effective lubrication reduces friction and allows you to "regain" power at the rear wheel while pushing the same watts at the crank.

Graph 3 – Profilometer Readings from Pin-on-Disc Test

The above pictures show the surface of the hardened steel disc after finishing the test—showing how much damage the surface of the disc suffered.

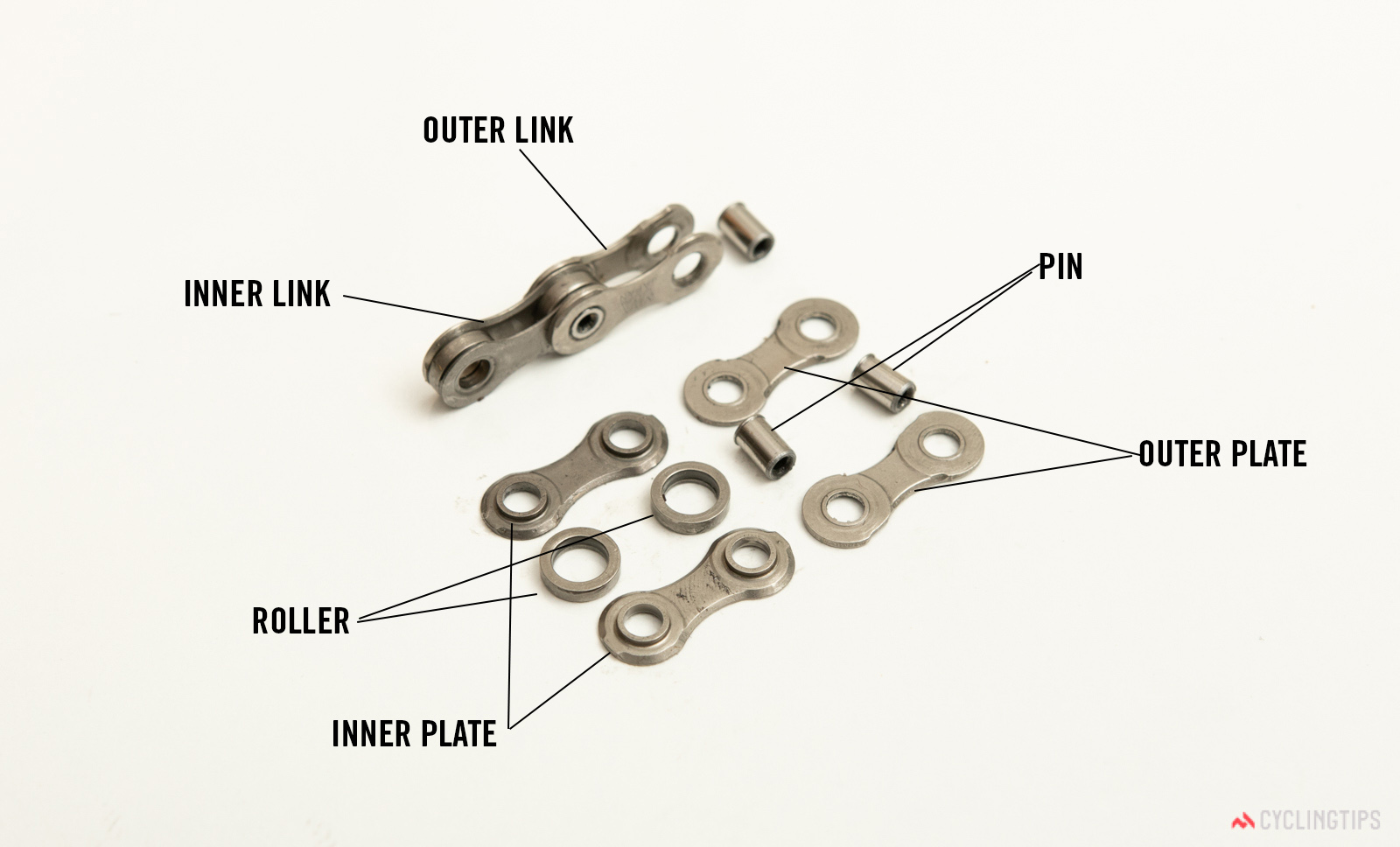

Most of the friction in the chain comes from two surface pairs: the inner plate rubbing on the outer plate, and the roller rubbing on the pin.

Before I tell of my experiences with absoluteBLACK GRAPHENlube, here is the science bit (taken from the absoluteBLACK website)...

GRAPHENlube – 5 Claimed Advantages

- 5 Watt efficiency gain over 900 kilometres, in dry conditions

- Extend the life of your drivetrain

- Repels water and does not attract dirt

- Dry paste-like coating stays on the chain for up to 1800 kilometres in dry conditions

- Does not contain harmful solvents

GRAPHENlube – The Development and Product

GRAPHENlube is a wax-based water emulsion with a special mix of high-purity graphene. It is liquid when you apply it, but becomes almost solid when it dries on the chain.Wax-based lubricants show far greater tolerance to water and dirt contamination—successfully separating moving chain parts from abrasion and filling in all the imperfections on friction surfaces (see appendix).

Graphene—the wonder material (incredibly high cost) is a great chain lubricant additive for several reasons: it has an extremely low friction coefficient in all environments; it is far stronger than any other known material; it clings to metal surfaces such as chain parts; and it also repels water and is not permeable to air—reducing oxidative stress on metal surfaces. A single atom layer is enough to reduce friction.

It took absoluteBLACK two years to find the right ratio of crumpled to non-crumpled graphene; the correct size of graphene platelets; the dispersion rate of agglomerates; the best concentration; and to find a low-friction hydrocarbon emulsion base that would stay on the chain for a very long time and not chip away like paraffin wax. The result, is a new category of performance chain lubricant.

GRAPHENlube – The Science

GRAPHENlube is not about saving watts, it is about reducing watts lossed due to friction.

These results came from an independent friction test: at 250 watt resistance, 100 rpm cadence, 40 km/h speed, 25c temperature, and 25% humidity. The test continued until chains reached a 10 watt power efficiency loss.

This test reveals how lubricant and friction changes over distance ridden. The higher the number, the more watts lost. With wet lubes, friction first decreases because the chain gets drier and therefore 'stiction' decreases; when it reaches a dry state, the friction then increases due to a starvation of lubricant and abrasion. For dry lubes, 'stiction' is minimal at the start—so friction simply increases due to the coating wearing out.

Why is this test important? When you pedal the force/torque is transferred through the chain to the rear hub. However, power generated at the crank does not equal power at the hub—due to frictional power losses.

The majority of friction loses are due to hundreds of articulations of chain link elements per second. The above graph shows how much less power is delivered to the rear wheel compared to the power at the crank; or in other words, how much you would have to increase the power at the crank if you wanted to retain the same speed with passing kilometres. Even the best lubricated chain in perfect laboratory conditions still generates about 4 watts of frictional loss from the start—for example, a Shimano Dura-Ace chain straight out of the box varies between 6.5-13 watt loss.

How can we minimise this loss and keep it low for a long time? The answer, is through best possible lubrication. Effective lubrication reduces friction and allows you to "regain" power at the rear wheel while pushing the same watts at the crank.

Graph 2 – Pin-on-Disc Test – Tribological Friction and Wear

An independent study conducted by University of Science and Technology in Krakow, Poland. This test measures friction coefficients by spinning a lubricant-coated metal disc under a static ball being pressed to the disc with a known force. The test mimics the conditions of rubbing an inner chain link hole with the chain pin surface.

The calculated distance compared to the number of cycles gives a hypothetical 300 kilometre chain life. The increase in friction means that the lube wears out under the pin—leading to more abrasion and further friction due to loose metal particles.

There is a good correlation to Graph 1—explaining the wattage loss. You can also see how the amount of the lubricant impacts the friction coefficient—so never skimp on chain lube!

Graph 3 – Profilometer Readings from Pin-on-Disc Test

The above pictures show the surface of the hardened steel disc after finishing the test—showing how much damage the surface of the disc suffered.

The amount and depth of abrasion is almost five times bigger on the top sample compared to the bottom one. This is the snowball effect of lubricant deprivation; it creates loose metal particles, which in turn increase the abrasion effect, which then creates more loose particles.

Graph 4 – ZFC Test – Chain Wear Percentage in Various Riding Conditions

Graph 4 – ZFC Test – Chain Wear Percentage in Various Riding Conditions

Every block represents 1000 kilometres. The test is stopped when accumulation of chain-wear reaches 100 percent. The chain is left contaminated as you proceed from one block of testing to the next one (going from left to right).

The results clearly show how some lubricants are more effective at reducing chain-wear than others.

Scientific Tests – Summary

The above graphs speak for themselves. AbsoluteBLACK GRAPHENlube demonstrates that it can reduce friction to a greater extent than any other tested chain lube; this translates directly into increased transmitted power to the rear wheel hub.

Furthermore, absoluteBLACK GRAPHENlube reduces chain wear and component damage in all conditions—saving on the significant cost of replacing worn-out drivetrain parts.

Real World Testing – Summary

So, did the laboratory tests translate into real world benefits?

I have been testing the absoluteBLACK GRAPHENlube on mountain bikes, gravel bikes, road bikes, and touring bikes over the last three months. The results are indeed outstanding...

In dry summer conditions, most lubricants last at most 300 kilometres before needing reapplication. GRAPHENlube will easily last 500 to 700 kilometres of riding, depending on whether it is dusty gravel or clean tarmac you are riding on.

In wet conditions, most lubricants will last at most 200 kilometres before needing reapplication. GRAPHENlube lasted 400 kilometres before my chain started to make an audible friction-signalling sound.

The verdict... it works.

If you are looking for a lubricant that could reduce the time you need to spend cleaning and lubing your bike; that could reduce the amount of times you need to replace components; and crucially could reduce the loss of power incurred from drivetrain friction... it is well worth looking at this lubricant from absoluteBLACK.

NOTE: There is a unique application process for absoluteBLACK GRAPHENlube—vital to how well it performs—watch the video here.

Appendix – Why You Should Stop Using Wet Oil-Based Chain Lubricants

Most of the friction in the chain comes from two surface pairs: the inner plate rubbing on the outer plate, and the roller rubbing on the pin.

At a microscopic level, the below photo shows a cross section of the inner plate at the point where hole for the pin is. It is clear in the image that the surface is not straight or even—but contains a lot of imperfections.

Oil-based lubricants are not capable of creating a sufficient boundary film to lubricate the two surfaces, because unevenness creates too much metal-on-metal contact.

Wax-based lubricants perform better because they are semi-solid in state, and therefore capable of filling gaps and separating the surfaces that create friction.

For the same reason, thin film coatings wear out relatively faster—as they are not thick enough to fill in all the gaps.

Tim Wiggins is an absoluteBLACK Global Ambassador

Comments

Post a Comment